The Challenge

How can we reduce downtime and accelerate maintenance?

Helicopters are among the most critical and expensive assets in any fleet, where every hour on the ground creates operational delays, availability gaps, and substantial financial impact. Traditional diagnostic workflows depend heavily on manual inspection, fragmented maintenance data, and complex interactions between aircraft subsystems. This often results in lengthy troubleshooting cycles and preventable downtime.

To address these challenges, our partner needed a smarter way to increase aircraft uptime, reduce non-productive maintenance hours, and speed up decision-making around both diagnosis and repair. As partners, we aimed to modernize maintenance operations with a solution that could support technicians without replacing their judgement, while improving accuracy, consistency, and readiness across the fleet.

The Solution

AI-Enhanced Diagnostics and Maintenance Planning

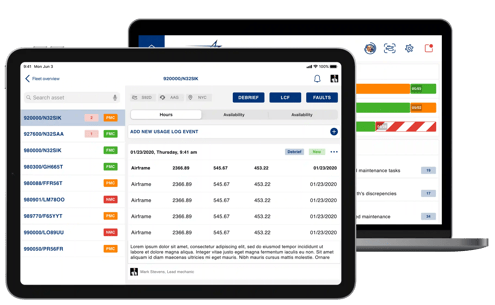

Empact Norway partnered with Lockheed Martin to develop a module which integrates into our Empact Asset Maintenance. Together, we created an adaptive maintenance approach which includes AI-driven diagnostics with the expertise of human technicians where it matters most.

The system analyzes historical maintenance logs, sensor data, part-failure patterns, and mission profiles to identify the most probable root causes of a fault. AI models automatically prioritize the areas of the aircraft most likely to require attention, while technicians retain full control over verification, repair workflows, and safety-critical decisions.

This hybrid model ensures a balanced approach, allowing a complex pattern recognition and predictive insights through AI, while human maintainers can focus on tasks requiring judgment, compliance, and their hands-on experience. At the same time, repair sequences and spare-part decisions are optimized automatically. This gives planning teams continuous real-time visibility into aircraft status, readiness, and expected completion times. The result: faster, more accurate, more predictable end-to-end maintenance processes.

The Outcome

Higher Uptime through AI-supported maintenance

By shifting diagnosis and repair planning to a combined AI-and-human workflow, the organization achieved measurable operational improvements across the helicopter fleet. From faster damage assessment and more accurate repair planning to reduced aircraft downtime: The gained real-time insights into maintenance needs empower decision-makers to allocate resources efficiently and maintain fleet readiness.

Faster fault prioritization, streamlined repair planning, and improved predictability have all contributed to stronger readiness and more reliable mission scheduling. The solution supports improved operational readiness while modernizing maintenance processes for future scalability.

35% Faster Spare-Part Cyclebetter fault prediction reduces time to identify and source parts. |

12% Increase in Overall

|

Reduced Technician

|

Greater Predictability & Fleet Readinessthrough more proactive maintenance planning and processes. |

The Customer

Lockheed Martin is the world’s largest supplier in the

defence industry with +100.000 employees

With a annual turnover of over 300 billion DKK. As solutions partner to Sikorsky, a Lockheed Martin company, Empact has delivered a digital workplace solution to their employees.

5 min read

5 min read

.png?width=335&height=335&name=Website%20media%20(72).png)